Nitrogen and Phosphorus Waste Water Treatment by Denitrification-Hydrolytic Acidification-Anaerobic-Anoxic-MBR Process

An industrial park has a number of LED

manufacturers, manufacturers and machinery manufacturers, and is a

semiconductor production and research and development base. According to the

production process of each plant, the sewage is collected and treated in

stages. The chemical reaction-coagulation sedimentation method is used for the

high-phosphorus wastewater, and the treated wastewater is mixed with the

non-phosphorus wastewater that has been pretreated by various factories, and

then the mixed wastewater is treated by the

denitrification-hydrolysis-acidification-anaerobic-anoxic-MBR process. deal

with.

1 Project overview

1.1 Design water quantity and water quality

The amount of wastewater in the high phosphorus section is

less, and the volume flow is 200 m3/d. The water quality of wastewater is: pH

7-10, COD=186 mg/L, ρ(TP)=16 mg/L, ρ(SS)=120 mg/L.

The wastewater in the high phosphorus section is mixed with

non-phosphating water after treatment, the total volume flow is 1 200 m3/d, and

the designed treatment capacity is 50 m3/h. Mixed influent pH is 6~9, COD=450

mg/L, BOD5=80 mg/L, ρ(TN)=86mg/L, ρ(NO3--N)=50-60 mg/L, ρ(TP )=7.4 mg/L.

1.2 Process flow

The wastewater in the high phosphorus section has the characteristics of high suspended solids and phosphorus content. For such wastewater, the coagulation and sedimentation method is used to remove it.

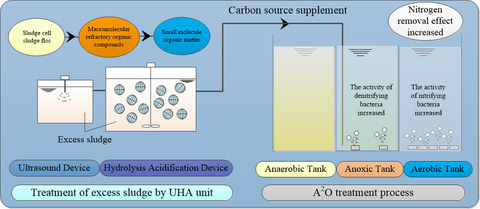

The pretreated non-phosphate wastewater after treatment by various enterprises has high nitrogen and phosphorus content and low carbon content and the characteristics of low biodegradability, first denitrification treatment of sewage to remove part of nitrate nitrogen, carbon source should be added before denitrification to ensure sufficient carbon source.

The effluent after

denitrification is hydrolyzed and acidified to degrade the refractory

substances in the sewage. Finally, the sewage goes through the A2O process to

remove COD, TN, and TP.

1.3 Design description of main structures

1.3.1 Phosphating wastewater pretreatment conditioning tank

The untreated high phosphorus-containing wastewater from each

enterprise is transported to the sewage treatment plant through tank trucks,

and enters the pretreatment adjustment tank to uniformize the water quality and

quantity of the phosphorus-containing wastewater, and control the sewage to

enter the subsequent treatment facilities according to a certain flow.

1.3.2 Phosphating wastewater coagulation sedimentation tank

After the pH adjustment of the phosphating wastewater, NaOH, calcium chloride, polyaluminum chloride (PAC) and polyacrylamide (PAM) were sequentially added to the wastewater to form large particle precipitation by flocculation.

The inclined plate placed in the precipitation area divides the

precipitation area into several areas, thereby increasing the precipitation

area, accelerating the precipitation speed, improving the precipitation efficiency,

and achieving the purpose of separation of mud and water.

1.3.3 Neutralization treatment reaction tank

Adjust the pH of the effluent from the inclined plate

sedimentation tank to neutral and then discharge it to the non-phosphating

wastewater adjustment tank for further treatment.

1.3.4 Non-phosphating wastewater conditioning tank

The water quality of each enterprise and the treated

phosphating wastewater are uniformly treated to ensure the stability of the

water inflow to the subsequent facilities.

1.3.5 Primary sedimentation tank

The pool is provided with a scum collection bucket, a sedimentation sludge collection bucket and a sludge discharge pipe. The scum floating on the water surface enters the scum collection bucket through the slag hanger on the upper part of the scraper.

The sludge and sand particles deposited at the bottom of the pool are scraped into the sludge collection bucket by the scraper, and the sludge is discharged by regularly opening the sludge.

The valve is used to discharge the sludge, and the sludge is discharged

into the sludge collection tank.

1.3.6 Denitrification tank

After the primary sedimentation, the sewage contains high

nitrate nitrogen, and a certain amount of glucose is added to the tank, and the

nitrate in the sewage is converted into nitrogen by the denitrifying bacteria

in the tank, and the added organic matter is converted into carbon dioxide and

water at the same time. The designed HRT was 4 h.

1.3.7 Hydrolysis and acidification pool

The macromolecular organic matter contained in the comprehensive sewage is difficult to be directly degraded by aerobic microorganisms.

In the hydrolytic acidification stage, the macromolecular

organic matter in the water is decomposed into easily biochemically small

molecular organic matter by the hydrolysis acidifying bacteria, thereby

improving the biodegradability of the wastewater. The effect of subsequent

biochemical treatment. The designed HRT was 8 h.

1.3.8 A2O

The phosphorus accumulating bacteria in the anaerobic tank absorb and degrade the organic matter quickly, and at the same time release the phosphorus in the body to prepare for the overabsorption of phosphorus under aerobic conditions. The designed HRT is 2 h.

The denitrifying bacteria in the anoxic tank use the The nitrate in the return water of the aerobic tank converts the organic matter from the effluent of the anaerobic tank into carbon dioxide and water, and at the same time, the nitrate in the return water of the aerobic tank is converted into nitrogen to realize biological denitrification and denitrification.

The designed HRT is 4 h. In the aerobic section, a membrane bioreactor (MBR) is used, and membrane filtration (microfiltration or ultrafiltration) is used to replace the sedimentation tank in the activated sludge process to achieve sludge-water separation. Under aerobic conditions of sewage, phosphorus-accumulating bacteria absorb excess phosphorus to achieve biological phosphorus removal, and at the same time complete the nitrification of ammonia nitrogen and the oxidation of organic matter.

Microorganisms and

other suspended solids are intercepted and separated by the membrane module,

the water is pumped to the intermediate pool by the suction pump through the

membrane module, and the excess sludge is discharged into the sludge collecting

pool. The designed HRT was 6 h.

1.4 Main equipment

The main structures and equipment are shown in Table 1 and

Table 2.

2 Debug and run

2.1 Chemical dephosphorization control of high phosphorus

wastewater

The high-phosphorus wastewater contains a lot of phosphate radicals. According to the nature of the wastewater, sodium hydroxide, calcium chloride, PAC and PAM are added to the coagulation and sedimentation tank of the phosphating wastewater in sequence, and the pH is controlled at 9.0 to 10.5.

The neutralization reaction tank is used to neutralize excess alkali, and

the pH is maintained at 7.5 to 8.0. The treated sewage is discharged into the

non-phosphating wastewater conditioning tank for subsequent treatment.

2.2 Activated sludge culture

Activated sludge cultivation adopts the method of inoculation and domestication. The inoculated sludge is taken from the dewatered sludge of the urban sewage treatment plant, and each unit is dosed according to 1% of its own volume. Then turn on the fan in turn to supply air to the denitrification, hydrolysis acidification and eutrophication units, turn on the anaerobic tank, and stir with a submersible mixer in the anoxic tank.

During the incubation period, the mass ratio of C, N, and P in the water should be kept at about 100:5:1. In the initial stage of commissioning, the organic load and hydraulic load are controlled at 1/4 of the design load, and the pH is controlled within the appropriate parameter range of each reaction unit.

In order to ensure that the nutrients and pH of the subsequent processing unit can be stabilized within the appropriate range.

Appropriate dextrose and sodium hydroxide can be added

to the treatment unit. After stable operation, 2.8 g of glucose was put into

the denitrification tank to provide sufficient carbon source for each ton of

sewage treated.

2.3 MBR debugging

When MBR is carried out, the biological treatment system is firstly cultivated with activated sludge. In the early stage of culturing, since the sludge has not been formed in large quantities and the sludge content is low, if the water is pumped from the membrane module by the suction pump, the pollution of the separation membrane in the aerobic tank will be aggravated, so the mass concentration of the sludge reaches 4 g.

Before /L, it is not suitable to start the suction pump to pump water from the membrane module, and choose the operation mode of intermittent water intake, gas stop, sedimentation and drainage from the temporary drainage pipe.

When the sludge

proliferates and reaches the required content, the number of suction pumps and

blowers to be turned on is determined according to the amount of influent

water. When the water output of the suction pump is turned on, it should be

controlled at about 1/3 of the designed water output, and should not be too

large; after 1 week of operation, it can be increased to about 2/3 of the

designed water output; after another 1 week of operation, adjust to the

designed water output.

2.4 Running effect

After 4 months of debugging, the effluent quality of each

structure is shown in Table 3.

It can be seen from Table 3 that the removal rates of COD, TN

and TP after treatment are 86.7%, 84.4% and 92%, respectively, and all effluent

indicators can reach the Grade A standard of GB 18918-2002.

Conclusion

For industrial parks, sewage of similar nature can be

centrally treated, which can not only reduce the cost of enterprise sewage

treatment, but also save resources.

Using denitrification-hydrolysis-acidification-anaerobic-anoxic-MBR

process to treat wastewater, the treatment effect is stable, and the effluent

is in the first-class A standard in GB 18918-2002. After further operation,

advanced treatment of sewage can be considered, and reverse osmosis technology

can be used to reuse sewage.

Comments

Post a Comment